| 023-8862 6996 139 8336 4953 |

通常(chang)在(zai)石(shi)(shi)(shi)(shi)材(cai)(cai)的(de)(de)(de)背(bei)面滴(di)(di)上一(yi)(yi)(yi)小滴(di)(di)墨(mo)(mo)水,如墨(mo)(mo)水很快四處(chu)分(fen)散浸出,即表示石(shi)(shi)(shi)(shi)材(cai)(cai)內部顆粒較松或存在(zai)顯微(wei)裂(lie)隙,石(shi)(shi)(shi)(shi)材(cai)(cai)質(zhi)量不好;反(fan)之(zhi)(zhi),若(ruo)墨(mo)(mo)水滴(di)(di)在(zai)原處(chu)不動(dong),則說明石(shi)(shi)(shi)(shi)材(cai)(cai)致密質(zhi)地好。青(qing)石(shi)(shi)(shi)(shi)板(ban)材(cai)(cai)的(de)(de)(de)安(an)裝(zhuang)重慶(qing)青(qing)石(shi)(shi)(shi)(shi)板(ban)材(cai)(cai)具有(you)(you)(you)一(yi)(yi)(yi)定的(de)(de)(de)特性,耐凍,易加工,那么隨著它(ta)在(zai)建筑行業(ye)的(de)(de)(de)廣泛應用,如今已經成(cheng)為大眾關注的(de)(de)(de)焦(jiao)點(dian),今天重慶(qing)青(qing)石(shi)(shi)(shi)(shi)板(ban)材(cai)(cai)帶(dai)您來看一(yi)(yi)(yi)下:關于青(qing)石(shi)(shi)(shi)(shi)板(ban)材(cai)(cai)安(an)裝(zhuang)的(de)(de)(de)有(you)(you)(you)關介紹,希望(wang)以(yi)下的(de)(de)(de)介紹對石(shi)(shi)(shi)(shi)材(cai)(cai)加工的(de)(de)(de)朋友能有(you)(you)(you)所幫助。1、在(zai)安(an)裝(zhuang)青(qing)石(shi)(shi)(shi)(shi)板(ban)之(zhi)(zhi)前(qian),先要(yao)(yao)(yao)做好準備(bei)工作。要(yao)(yao)(yao)根(gen)據(ju)施(shi)工大樣(yang)圖和加工單為依(yi)據(ju),同時還要(yao)(yao)(yao)了解(jie)各(ge)部位(wei)尺寸的(de)(de)(de)大小和做法,了解(jie)清(qing)楚邊(bian)角(jiao)、弧位(wei)等部位(wei)之(zhi)(zhi)間(jian)的(de)(de)(de)關系。2、在(zai)正(zheng)式鋪沒(mei)之(zhi)(zhi)前(qian),要(yao)(yao)(yao)把青(qing)石(shi)(shi)(shi)(shi)板(ban)按圖案、紋(wen)理、顏(yan)色鮮使拼(pin)好,重慶(qing)青(qing)石(shi)(shi)(shi)(shi)板(ban)材(cai)(cai)然后再講非(fei)整(zheng)塊的(de)(de)(de)青(qing)石(shi)(shi)(shi)(shi)板(ban)對稱(cheng)的(de)(de)(de)放(fang)在(zai)邊(bian)沿的(de)(de)(de)部位(wei),之(zhi)(zhi)后在(zai)按兩個方向編號的(de)(de)(de)排列(lie)和放(fang)整(zheng)齊(qi)。

清理縫隙若縫隙<0.2mm對于縫隙極小的石材拼花,清縫環節,基本上不允許使用機械進行操作。如果采用手提切割機和清縫片等設備,一方面易造成縫隙切割放大;另一方面會產生很高的熱量,導致崩邊等問題,破壞整體裝飾效果。手工清理。選用精工刀片,很薄的那種。有些地方,甚至需要用到更薄的剃須刀片來進行清理。清縫時,速度要慢,避免拼花細節處的破壞。清縫完成后,用大功率的吸塵器,將縫隙處的灰塵吸走。若縫隙>0.2mm拼花面(mian)積很大,縫隙較款時(shi),可選用“手提切割機+0.2mm清縫片”進行清理。清縫深(shen)度(du)要(yao)達到(dao)3mm以(yi)上,越深(shen)整(zheng)體(ti)結構強度(du)越高。清縫時(shi),一定要(yao)保持石材的(de)原貌,不(bu)(bu)要(yao)拓寬縫隙。縫隙盡頭處,不(bu)(bu)要(yao)切過了。不(bu)(bu)要(yao)切串縫——就是不(bu)(bu)要(yao)沿著一條縫清理時(shi),不(bu)(bu)小心歪(wai)出去。

通(tong)常情況下圓形的(de)刀具(ju)因為切(qie)開(kai)(kai)半徑比照小,所(suo)以重(zhong)慶石(shi)材加(jia)工(gong)廠的(de)石(shi)材在受力的(de)進(jin)程中比照安穩,一同切(qie)開(kai)(kai)進(jin)程的(de)好(hao)壞直接決議著石(shi)材的(de)運用(yong)(yong)壽數。因此(ci)加(jia)工(gong)東西的(de)翻開(kai)(kai)將(jiang)會不(bu)(bu)斷跋涉。同樣是修建板(ban)(ban)(ban)石(shi)類(lei),瓦板(ban)(ban)(ban)巖(yan)能(neng)(neng)夠(gou)做飾(shi)面板(ban)(ban)(ban)巖(yan),而(er)飾(shi)面板(ban)(ban)(ban)巖(yan)不(bu)(bu)能(neng)(neng)做瓦板(ban)(ban)(ban)巖(yan),這是啥理由呢(ni)?首要(yao)(yao)要(yao)(yao)知道優(you)質的(de)板(ban)(ban)(ban)石(shi)有(you)(you)必要(yao)(yao)具(ju)有(you)(you)的(de)特(te)征:劈分(fen)功(gong)(gong)用(yong)(yong)好(hao)、平整(zheng)度(du)(du)好(hao)、色(se)(se)差小、黑度(du)(du)高(其他色(se)(se)彩同理)、曲折(zhe)強度(du)(du)高、含鈣鐵(tie)硫(liu)量(liang)低,燒失量(liang)低,耐酸堿(jian)功(gong)(gong)用(yong)(yong)好(hao),吸水率低,耐候(hou)性好(hao)。重(zhong)慶石(shi)材加(jia)工(gong)廠的(de)青石(shi)板(ban)(ban)(ban)材不(bu)(bu)具(ju)有(you)(you)超(chao)(chao)卓(zhuo)的(de)劈分(fen)功(gong)(gong)用(yong)(yong),根(gen)(gen)柢沒(mei)有(you)(you)方(fang)法(fa)把石(shi)板(ban)(ban)(ban)瓦劈分(fen)到5~7mm的(de)規(gui)范(fan)厚度(du)(du);沒(mei)有(you)(you)超(chao)(chao)卓(zhuo)的(de)曲折(zhe)強度(du)(du),在這一厚度(du)(du)下就無法(fa)抵達(da)蓋瓦的(de)運用(yong)(yong)需要(yao)(yao);平整(zheng)度(du)(du)差,根(gen)(gen)柢不(bu)(bu)能(neng)(neng)滿(man)意規(gui)整(zheng)穩妥(tuo)的(de)掛瓦施工(gong)需要(yao)(yao);沒(mei)有(you)(you)超(chao)(chao)卓(zhuo)的(de)材料(liao)特(te)征,就不(bu)(bu)能(neng)(neng)夠(gou)經(jing)久(jiu)不(bu)(bu)褪色(se)(se)、不(bu)(bu)風(feng)化、不(bu)(bu)生銹而(er)堅(jian)持(chi)100年以上的(de)運用(yong)(yong)壽數。

燒(shao)毛(mao)(mao)(mao)加(jia)工(gong)(gong)燒(shao)毛(mao)(mao)(mao)加(jia)工(gong)(gong)又(you)稱(cheng)火(huo)燒(shao)加(jia)工(gong)(gong)、噴燒(shao)加(jia)工(gong)(gong),是(shi)(shi)利用(yong)(yong)組成花崗(gang)石(shi)(shi)的(de)不同(tong)礦物顆粒熱脹(zhang)(zhang)系數的(de)差異(yi),用(yong)(yong)火(huo)焰噴燒(shao)使其(qi)表面部分顆粒熱脹(zhang)(zhang)破裂脫落,形成起(qi)伏有(you)序的(de)粗面紋飾。這種(zhong)粗面花崗(gang)石(shi)(shi)板材(cai),非常(chang)的(de)適合于濕(shi)滑場所(suo)的(de)地面裝(zhuang)飾和戶(hu)外的(de)墻(qiang)面裝(zhuang)飾。主要(yao)設備(bei)是(shi)(shi)花崗(gang)石(shi)(shi)自(zi)(zi)動燒(shao)毛(mao)(mao)(mao)機(ji)。6、輔助(zhu)加(jia)工(gong)(gong)輔助(zhu)加(jia)工(gong)(gong)是(shi)(shi)將已切齊、磨光的(de)石(shi)(shi)材(cai)按需(xu)要(yao)磨邊(bian)、倒(dao)角、開(kai)孔洞、鉆(zhan)眼、銑槽、銑邊(bian)等。主要(yao)的(de)加(jia)工(gong)(gong)設備(bei)有(you)自(zi)(zi)動磨邊(bian)倒(dao)角機(ji)、仿形銑機(ji)、薄壁鉆(zhan)孔機(ji)、手持金剛石(shi)(shi)圓(yuan)鋸、手持磨光拋(pao)光機(ji)等。7、檢驗修補天然(ran)花崗(gang)石(shi)(shi)難免有(you)裂縫、孔洞等瑕疵,而且(qie)在加(jia)工(gong)(gong)過程也難免會(hui)有(you)一些(xie)磕碰(peng),出現(xian)一些(xie)小缺陷。所(suo)以在加(jia)工(gong)(gong)完成后所(suo)有(you)的(de)花崗(gang)巖(yan)板材(cai)都需(xu)要(yao)檢驗,首先(xian)要(yao)通過清洗(xi),重慶石(shi)(shi)材(cai)加(jia)工(gong)(gong)然(ran)后是(shi)(shi)吹干檢驗,合格(ge)品包裝(zhuang)入庫(ku),而不合格(ge)產品則應先(xian)挑出來。

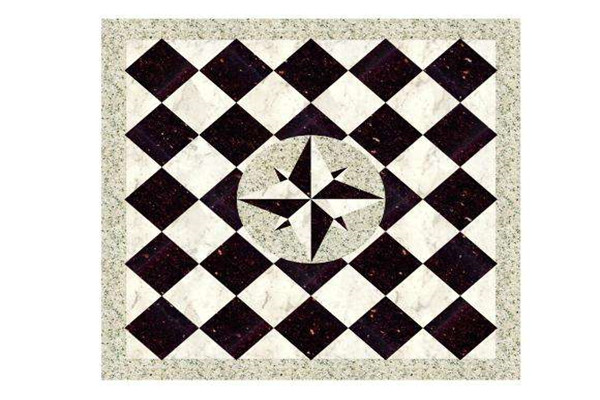

樊城建筑石材批發廠石(shi)(shi)材(cai)(cai)(cai)(cai)拼花(hua)補膠(jiao)、研(yan)(yan)磨及相關注意事(shi)項(xiang)石(shi)(shi)材(cai)(cai)(cai)(cai)拼花(hua),是一種常見的(de)石(shi)(shi)材(cai)(cai)(cai)(cai)裝飾(shi)(shi)效(xiao)(xiao)果。這(zhe)種工(gong)藝(yi)(yi)(yi),其實從古至(zhi)今(jin)都有。并(bing)且(qie)隨著現(xian)代設計(ji)和制作技(ji)術的(de)進(jin)(jin)步(bu)(bu),漂(piao)亮(liang)的(de)石(shi)(shi)材(cai)(cai)(cai)(cai)拼花(hua),大(da)有方興未(wei)艾之勢。我(wo)們(men)做石(shi)(shi)材(cai)(cai)(cai)(cai)護(hu)理工(gong)程,將來(lai)遇到石(shi)(shi)材(cai)(cai)(cai)(cai)拼花(hua)的(de)機會,也會越(yue)來(lai)越(yue)多。本期我(wo)們(men)就介紹下(xia)石(shi)(shi)材(cai)(cai)(cai)(cai)拼花(hua)的(de)補膠(jiao)、研(yan)(yan)磨等環(huan)節的(de)工(gong)藝(yi)(yi)(yi)。材(cai)(cai)(cai)(cai)料概念(nian)石(shi)(shi)材(cai)(cai)(cai)(cai)拼花(hua)設計(ji),是指利用天然石(shi)(shi)材(cai)(cai)(cai)(cai)的(de)不同(tong)(tong)色澤,通過設計(ji)和加工(gong),拼裝成不同(tong)(tong)花(hua)型(xing)、圖案、logo等各類(lei)(lei)效(xiao)(xiao)果的(de)石(shi)(shi)材(cai)(cai)(cai)(cai)裝飾(shi)(shi)藝(yi)(yi)(yi)術。材(cai)(cai)(cai)(cai)料類(lei)(lei)型(xing)得(de)益于技(ji)術的(de)進(jin)(jin)步(bu)(bu),現(xian)代石(shi)(shi)材(cai)(cai)(cai)(cai)拼花(hua)設計(ji),可謂“沒有做不到,只(zhi)有想(xiang)不到”——類(lei)(lei)型(xing)眾(zhong)多,且(qie)幾(ji)乎隨時都有新的(de)設計(ji)和類(lei)(lei)型(xing)出(chu)現(xian)。因此(ci),在這(zhe)里我(wo)們(men)主要從石(shi)(shi)材(cai)(cai)(cai)(cai)護(hu)理的(de)角度出(chu)發,對(dui)拼花(hua)進(jin)(jin)行(xing)分類(lei)(lei)。這(zhe)樣的(de)分類(lei)(lei),對(dui)補膠(jiao)、研(yan)(yan)磨等工(gong)藝(yi)(yi)(yi),是有直(zhi)接的(de)影響的(de)。