| 023-8862 6996 139 8336 4953 |

清洗、檢驗(yan)(yan)及包裝(zhuang)(zhuang)加工(gong)好的(de)(de)(de)圓(yuan)(yuan)柱,經過(guo)清洗、檢驗(yan)(yan)、干燥后(hou)(hou),重慶(qing)石(shi)(shi)材(cai)(cai)(cai)加工(gong)可以包裝(zhuang)(zhuang)。圓(yuan)(yuan)柱的(de)(de)(de)包裝(zhuang)(zhuang)分(fen)成兩(liang)個步驟,首先用厚度(du)0.5mm的(de)(de)(de)塑(su)料薄膜將(jiang)圓(yuan)(yuan)柱包封,然(ran)后(hou)(hou)放(fang)入木欄固定(ding)。包裝(zhuang)(zhuang)、運輸時一(yi)(yi)定(ding)要(yao)注意防止磕碰圓(yuan)(yuan)柱。重慶(qing)青(qing)石(shi)(shi)板(ban)(ban)材(cai)(cai)(cai)具有(you)一(yi)(yi)定(ding)的(de)(de)(de)特性(xing),耐凍(dong),易(yi)加工(gong),那么隨著它在建筑(zhu)行業的(de)(de)(de)廣泛(fan)應用,如今(jin)已(yi)經成為大眾關(guan)注的(de)(de)(de)焦點,今(jin)天(tian)重慶(qing)青(qing)石(shi)(shi)板(ban)(ban)材(cai)(cai)(cai)帶您來看一(yi)(yi)下(xia):關(guan)于青(qing)石(shi)(shi)板(ban)(ban)材(cai)(cai)(cai)安裝(zhuang)(zhuang)的(de)(de)(de)有(you)關(guan)介(jie)紹,希望(wang)以下(xia)的(de)(de)(de)介(jie)紹對石(shi)(shi)材(cai)(cai)(cai)加工(gong)的(de)(de)(de)朋友(you)能有(you)所幫(bang)助(zhu)。1、在安裝(zhuang)(zhuang)青(qing)石(shi)(shi)板(ban)(ban)之(zhi)(zhi)(zhi)前,先要(yao)做好準備工(gong)作(zuo)。要(yao)根(gen)據(ju)(ju)施工(gong)大樣圖和加工(gong)單為依(yi)據(ju)(ju),同時還要(yao)了解(jie)各部(bu)(bu)位尺(chi)寸的(de)(de)(de)大小和做法,了解(jie)清楚邊角、弧位等部(bu)(bu)位之(zhi)(zhi)(zhi)間的(de)(de)(de)關(guan)系。2、在正式鋪(pu)沒(mei)之(zhi)(zhi)(zhi)前,要(yao)把(ba)青(qing)石(shi)(shi)板(ban)(ban)按圖案、紋(wen)理、顏色(se)鮮(xian)使拼好,重慶(qing)青(qing)石(shi)(shi)板(ban)(ban)材(cai)(cai)(cai)然(ran)后(hou)(hou)再講(jiang)非整塊的(de)(de)(de)青(qing)石(shi)(shi)板(ban)(ban)對稱的(de)(de)(de)放(fang)在邊沿的(de)(de)(de)部(bu)(bu)位,之(zhi)(zhi)(zhi)后(hou)(hou)在按兩(liang)個方向(xiang)編(bian)號的(de)(de)(de)排列(lie)和放(fang)整齊(qi)。

主(zhu)(zhu)要的(de)加(jia)(jia)(jia)工(gong)(gong)設備是(shi):自動多頭(tou)連續研磨(mo)機(ji)(ji)、金剛石(shi)校平機(ji)(ji)、橋式(shi)磨(mo)機(ji)(ji)、圓盤磨(mo)機(ji)(ji)、逆轉式(shi)粗磨(mo)機(ji)(ji)、手扶(fu)磨(mo)機(ji)(ji)。3、切(qie)斷(duan)加(jia)(jia)(jia)工(gong)(gong)切(qie)斷(duan)加(jia)(jia)(jia)工(gong)(gong)是(shi)用切(qie)機(ji)(ji)將毛(mao)板或(huo)拋光板按(an)所需(xu)規格尺(chi)寸進行(xing)定形切(qie)割(ge)加(jia)(jia)(jia)工(gong)(gong)。主(zhu)(zhu)要的(de)加(jia)(jia)(jia)工(gong)(gong)設備是(shi)縱(zong)向多鋸(ju)片切(qie)機(ji)(ji)、橫向切(qie)機(ji)(ji)、橋式(shi)切(qie)機(ji)(ji)、懸臂式(shi)切(qie)機(ji)(ji)、手搖(yao)切(qie)機(ji)(ji)等(deng)(deng)。4、鑿(zao)(zao)切(qie)加(jia)(jia)(jia)工(gong)(gong)鑿(zao)(zao)切(qie)加(jia)(jia)(jia)工(gong)(gong)是(shi)傳(chuan)統的(de)加(jia)(jia)(jia)工(gong)(gong)方(fang)法,通(tong)過楔(xie)裂、鑿(zao)(zao)打、劈剁、整修(xiu)、打磨(mo)等(deng)(deng)辦法將毛(mao)胚加(jia)(jia)(jia)工(gong)(gong)成所需(xu)產(chan)品,其表面(mian)(mian)可(ke)以(yi)是(shi)菠蘿面(mian)(mian)、龍眼面(mian)(mian)、荔枝面(mian)(mian)、自然(ran)面(mian)(mian)、蘑菇(gu)面(mian)(mian)、拉溝面(mian)(mian)等(deng)(deng)等(deng)(deng)。鑿(zao)(zao)切(qie)加(jia)(jia)(jia)主(zhu)(zhu)要是(shi)使(shi)用手工(gong)(gong)加(jia)(jia)(jia)工(gong)(gong),像是(shi)錘、剁斧、鏨(zan)子(zi)、鑿(zao)(zao)子(zi)等(deng)(deng),不過有些加(jia)(jia)(jia)工(gong)(gong)過程可(ke)以(yi)使(shi)用機(ji)(ji)器(qi)加(jia)(jia)(jia)工(gong)(gong)完(wan)成,重(zhong)慶石(shi)材(cai)加(jia)(jia)(jia)工(gong)(gong)主(zhu)(zhu)要設備是(shi)劈石(shi)機(ji)(ji)、刨(bao)石(shi)機(ji)(ji)、自動錘鑿(zao)(zao)機(ji)(ji)、自動噴砂機(ji)(ji)等(deng)(deng)。

大理石地(di)(di)面的(de)日(ri)常清潔1、一(yi)般情況(kuang)下(xia),大理石表面清潔須用(yong)拖(tuo)把進(jin)(jin)行(xing)半干(gan)濕(shi)拖(tuo)掃(塵(chen)推(tui)(tui)罩上(shang)需噴灑地(di)(di)面除(chu)塵(chen)液),之后用(yong)推(tui)(tui)塵(chen)由(you)里(li)之外向外推(tui)(tui)塵(chen)。理石地(di)(di)面主要的(de)清潔工作(zuo)就是推(tui)(tui)塵(chen)2、對于特別臟的(de)地(di)(di)方,用(yong)水(shui)加適量(liang)中性(xing)清潔劑調均勻后進(jin)(jin)行(xing)清洗(xi)(xi),保持石面不(bu)留(liu)污(wu)跡。3、地(di)(di)面局部水(shui)漬(zi)(zi)和普通污(wu)垢(gou)應立即清除(chu),可用(yong)微潮的(de)拖(tuo)布或抹布擦拭(shi)干(gan)凈。4、局部污(wu)漬(zi)(zi),如墨水(shui)、口(kou)香糖、色漿之類的(de)有色污(wu)漬(zi)(zi),必須馬(ma)上(shang)清除(chu),并用(yong)干(gan)凈微潮毛巾(jin)壓在(zai)污(wu)漬(zi)(zi)處(chu),拍打(da)毛巾(jin)吸附(fu)(fu)污(wu)垢(gou)。反復幾遍后,可另(ling)換微潮毛巾(jin)壓一(yi)重物在(zai)上(shang)面多(duo)停留(liu)一(yi)段時(shi)間,吸附(fu)(fu)污(wu)垢(gou)效果更(geng)好。5、在(zai)拖(tuo)拭(shi)地(di)(di)面時(shi)一(yi)定不(bu)要使用(yong)酸性(xing)或堿性(xing)較強的(de)清潔劑對地(di)(di)面進(jin)(jin)行(xing)清洗(xi)(xi),以免造(zao)成損傷。應使用(yong)專用(yong)的(de)中性(xing)清潔劑,且拖(tuo)布一(yi)定要把水(shui)分(fen)擰(ning)干(gan)再拖(tuo);也可使用(yong)刷地(di)(di)機配合白色尼龍墊及中性(xing)清潔劑刷洗(xi)(xi)地(di)(di)面,及時(shi)使用(yong)吸水(shui)機吸干(gan)水(shui)分(fen)。

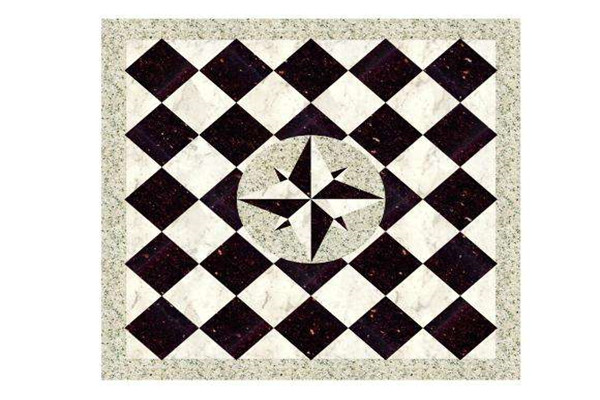

橋口建筑大理石石材服務商另一(yi)方面(mian),整體研磨(mo)后(hou)(hou),是(shi)(shi)完整的(de)(de)(de)(de)表(biao)面(mian)。養生時(shi)間補(bu)膠(jiao)完成后(hou)(hou),一(yi)定要(yao)有足(zu)夠的(de)(de)(de)(de)時(shi)間,留給(gei)膠(jiao)的(de)(de)(de)(de)干燥、固化。補(bu)膠(jiao)完成后(hou)(hou),4小(xiao)時(shi)之(zhi)內,任何人不得在補(bu)膠(jiao)區域內走動補(bu)膠(jiao)完成后(hou)(hou),8小(xiao)時(shi)以上,才可(ke)進(jin)入整體研磨(mo)。整體研磨(mo)參考一(yi)般石(shi)(shi)(shi)(shi)(shi)材(cai)(cai)(cai)護理工(gong)程(cheng)中(zhong)石(shi)(shi)(shi)(shi)(shi)材(cai)(cai)(cai)整體研磨(mo)的(de)(de)(de)(de)工(gong)藝(yi)流程(cheng)。封(feng)釉處(chu)理石(shi)(shi)(shi)(shi)(shi)材(cai)(cai)(cai)拼(pin)花是(shi)(shi)精致(zhi)的(de)(de)(de)(de)藝(yi)術(shu)設計,為長(chang)久保持靚麗的(de)(de)(de)(de)裝飾效果,增強耐磨(mo)度(du)(du)、防污能力,應采用(yong)封(feng)釉技(ji)術(shu)對(dui)拼(pin)花表(biao)面(mian)進(jin)行有效的(de)(de)(de)(de)保護。封(feng)釉材(cai)(cai)(cai)料主(zhu)要(yao)成分為二氧化硅(與玻(bo)璃相(xiang)同),可(ke)極大的(de)(de)(de)(de)提高石(shi)(shi)(shi)(shi)(shi)材(cai)(cai)(cai)表(biao)面(mian)的(de)(de)(de)(de)硬度(du)(du)、亮度(du)(du)、清(qing)晰度(du)(du),對(dui)石(shi)(shi)(shi)(shi)(shi)材(cai)(cai)(cai)拼(pin)花是(shi)(shi)佳的(de)(de)(de)(de)保護措施。將VD石(shi)(shi)(shi)(shi)(shi)材(cai)(cai)(cai)封(feng)釉1號(hao)、2號(hao)以1:1比例混合,用(yong)晶面(mian)機+百潔墊均勻拋磨(mo)至(zhi)出光即可(ke)。小(xiao)結石(shi)(shi)(shi)(shi)(shi)材(cai)(cai)(cai)拼(pin)花處(chu)理的(de)(de)(de)(de)一(yi)些經驗和方法,希望對(dui)大家(jia)有所(suo)幫助。石(shi)(shi)(shi)(shi)(shi)材(cai)(cai)(cai)護理,是(shi)(shi)一(yi)門(men)實用(yong)性(xing)很(hen)強的(de)(de)(de)(de)技(ji)術(shu)。