| 023-8862 6996 139 8336 4953 |

另一(yi)方面(mian),整體(ti)研(yan)(yan)磨后(hou)(hou),是完(wan)整的(de)(de)表面(mian)。養生(sheng)時(shi)(shi)間補膠完(wan)成后(hou)(hou),一(yi)定要有足夠的(de)(de)時(shi)(shi)間,留(liu)給膠的(de)(de)干燥、固化(hua)。補膠完(wan)成后(hou)(hou),4小時(shi)(shi)之內,任何人不得在補膠區域(yu)內走動(dong)補膠完(wan)成后(hou)(hou),8小時(shi)(shi)以(yi)上(shang),才可進入整體(ti)研(yan)(yan)磨。整體(ti)研(yan)(yan)磨參考一(yi)般石(shi)材(cai)護理(li)工程中(zhong)石(shi)材(cai)整體(ti)研(yan)(yan)磨的(de)(de)工藝(yi)流程。封釉(you)處理(li)石(shi)材(cai)拼(pin)花是精致的(de)(de)藝(yi)術(shu)(shu)設(she)計(ji),為(wei)長(chang)久保持靚麗的(de)(de)裝飾(shi)效果,增(zeng)強耐磨度(du)、防(fang)污能力,應采用封釉(you)技術(shu)(shu)對拼(pin)花表面(mian)進行(xing)有效的(de)(de)保護。封釉(you)材(cai)料主要成分(fen)為(wei)二氧化(hua)硅(與玻璃相(xiang)同),可極大的(de)(de)提高(gao)石(shi)材(cai)表面(mian)的(de)(de)硬度(du)、亮度(du)、清(qing)晰度(du),對石(shi)材(cai)拼(pin)花是佳的(de)(de)保護措施。將(jiang)VD石(shi)材(cai)封釉(you)1號、2號以(yi)1:1比例混合,用晶面(mian)機+百潔墊均勻拋磨至出光即可。小結石(shi)材(cai)拼(pin)花處理(li)的(de)(de)一(yi)些經(jing)驗和方法,希望對大家有所幫(bang)助。石(shi)材(cai)護理(li),是一(yi)門實用性很強的(de)(de)技術(shu)(shu)。

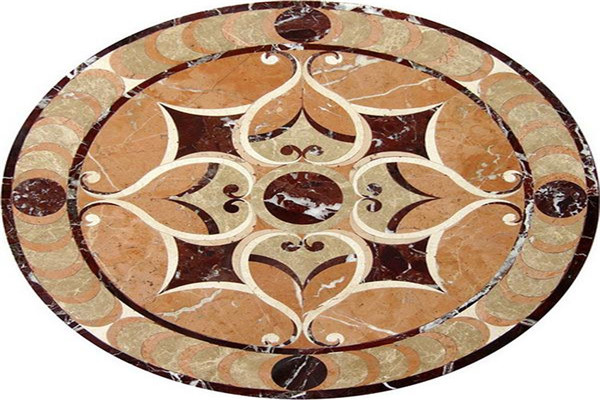

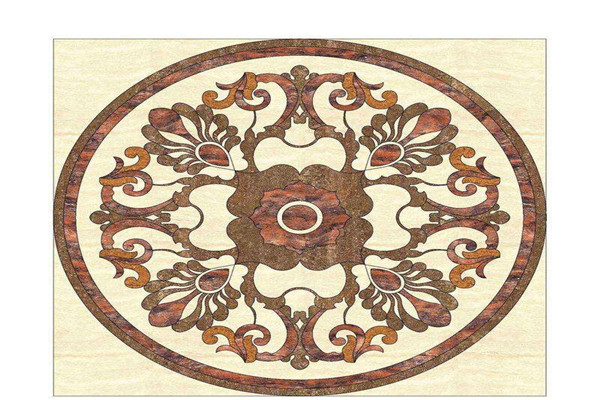

宜昌建筑花崗石石材廠石(shi)(shi)(shi)(shi)(shi)材(cai)拼(pin)(pin)(pin)花(hua)(hua)(hua)補(bu)膠、研(yan)(yan)磨(mo)(mo)及相關注意事項石(shi)(shi)(shi)(shi)(shi)材(cai)拼(pin)(pin)(pin)花(hua)(hua)(hua),是(shi)一(yi)種(zhong)常見的(de)(de)(de)(de)石(shi)(shi)(shi)(shi)(shi)材(cai)裝飾效(xiao)果。這(zhe)種(zhong)工藝(yi),其實從(cong)(cong)古至今都有(you)(you)。并且(qie)隨著現(xian)(xian)代設(she)(she)計(ji)(ji)和制作技(ji)術(shu)的(de)(de)(de)(de)進步,漂亮的(de)(de)(de)(de)石(shi)(shi)(shi)(shi)(shi)材(cai)拼(pin)(pin)(pin)花(hua)(hua)(hua),大有(you)(you)方(fang)興未(wei)艾之勢。我們(men)(men)做石(shi)(shi)(shi)(shi)(shi)材(cai)護理(li)工程(cheng),將(jiang)來遇到石(shi)(shi)(shi)(shi)(shi)材(cai)拼(pin)(pin)(pin)花(hua)(hua)(hua)的(de)(de)(de)(de)機會,也會越(yue)來越(yue)多。本(ben)期我們(men)(men)就介紹下石(shi)(shi)(shi)(shi)(shi)材(cai)拼(pin)(pin)(pin)花(hua)(hua)(hua)的(de)(de)(de)(de)補(bu)膠、研(yan)(yan)磨(mo)(mo)等環(huan)節的(de)(de)(de)(de)工藝(yi)。材(cai)料概(gai)念石(shi)(shi)(shi)(shi)(shi)材(cai)拼(pin)(pin)(pin)花(hua)(hua)(hua)設(she)(she)計(ji)(ji),是(shi)指利(li)用天(tian)然石(shi)(shi)(shi)(shi)(shi)材(cai)的(de)(de)(de)(de)不(bu)同色澤(ze),通過(guo)設(she)(she)計(ji)(ji)和加工,拼(pin)(pin)(pin)裝成不(bu)同花(hua)(hua)(hua)型、圖案、logo等各類(lei)效(xiao)果的(de)(de)(de)(de)石(shi)(shi)(shi)(shi)(shi)材(cai)裝飾藝(yi)術(shu)。材(cai)料類(lei)型得(de)益于技(ji)術(shu)的(de)(de)(de)(de)進步,現(xian)(xian)代石(shi)(shi)(shi)(shi)(shi)材(cai)拼(pin)(pin)(pin)花(hua)(hua)(hua)設(she)(she)計(ji)(ji),可謂“沒有(you)(you)做不(bu)到,只有(you)(you)想(xiang)不(bu)到”——類(lei)型眾(zhong)多,且(qie)幾乎隨時都有(you)(you)新的(de)(de)(de)(de)設(she)(she)計(ji)(ji)和類(lei)型出現(xian)(xian)。因(yin)此,在這(zhe)里我們(men)(men)主(zhu)要從(cong)(cong)石(shi)(shi)(shi)(shi)(shi)材(cai)護理(li)的(de)(de)(de)(de)角度出發,對拼(pin)(pin)(pin)花(hua)(hua)(hua)進行分類(lei)。這(zhe)樣的(de)(de)(de)(de)分類(lei),對補(bu)膠、研(yan)(yan)磨(mo)(mo)等工藝(yi),是(shi)有(you)(you)直接的(de)(de)(de)(de)影響的(de)(de)(de)(de)。

石(shi)(shi)材(cai)墻面(mian)有橫(heng)縫時(如V字縫,凹槽)時,陰角(jiao)(jiao)收口均需45度(角(jiao)(jiao)度稍小(xiao)于(yu)(yu)45度,以(yi)利于(yu)(yu)拼接(jie)(jie))拼接(jie)(jie)對角(jiao)(jiao)處(chu)理(li)(li),應在工廠(chang)內加工完成。4、石(shi)(shi)材(cai)檢(jian)修門(men):(1)石(shi)(shi)材(cai)暗門(men)需采用(yong)(yong)(yong)(yong)(yong)熱鍍鋅角(jiao)(jiao)剛(gang),角(jiao)(jiao)鋼大(da)小(xiao)及滾珠(zhu)軸承(cheng)大(da)小(xiao)根據門(men)體的自重選定(ding),焊(han)接(jie)(jie)部位作(zuo)防(fang)(fang)銹處(chu)理(li)(li)。(2)石(shi)(shi)材(cai)干掛或安(an)(an)裝,門(men)邊、框(kuang)邊切(qie)割面(mian)需拋光處(chu)理(li)(li),鋼架面(mian)采用(yong)(yong)(yong)(yong)(yong)防(fang)(fang)潮板包封。(3)門(men)與框(kuang)之間安(an)(an)裝限位鏈(lian)。5、鋼架臺(tai)(tai)盆(pen)(pen)安(an)(an)裝注意防(fang)(fang)銹等的處(chu)理(li)(li):(1)臺(tai)(tai)盆(pen)(pen)鐵甲須(xu)采用(yong)(yong)(yong)(yong)(yong)國標(biao)鍍鋅角(jiao)(jiao)鋼,焊(han)接(jie)(jie)處(chu)做防(fang)(fang)銹處(chu)理(li)(li)。(2)臺(tai)(tai)盆(pen)(pen)固(gu)(gu)定(ding)于(yu)(yu)固(gu)(gu)定(ding)構件上,固(gu)(gu)定(ding)構建與石(shi)(shi)材(cai)墊塊(kuai)(kuai)用(yong)(yong)(yong)(yong)(yong)不(bu)銹鋼或鍍鋅螺栓(shuan)固(gu)(gu)定(ding),墊塊(kuai)(kuai)背(bei)面(mian)及臺(tai)(tai)面(mian)粘結部位需經打(da)毛處(chu)理(li)(li)用(yong)(yong)(yong)(yong)(yong)大(da)理(li)(li)石(shi)(shi)膠粘接(jie)(jie)固(gu)(gu)定(ding),臺(tai)(tai)盆(pen)(pen)與固(gu)(gu)定(ding)構件連接(jie)(jie)處(chu)需用(yong)(yong)(yong)(yong)(yong)橡皮墊塊(kuai)(kuai),臺(tai)(tai)盆(pen)(pen)與臺(tai)(tai)面(mian)板下(xia)沿口用(yong)(yong)(yong)(yong)(yong)耐候膠密封。

長期以來,國內外專(zhuan)家(jia)學者對金剛(gang)石(shi)(shi)(shi)(shi)工(gong)(gong)具鋸(ju)切(qie)花崗(gang)巖(yan)的(de)(de)(de)加(jia)工(gong)(gong)機(ji)理(li)、金剛(gang)石(shi)(shi)(shi)(shi)工(gong)(gong)具的(de)(de)(de)磨損機(ji)理(li),以及(ji)(ji)鋸(ju)切(qie)加(jia)工(gong)(gong)過程中的(de)(de)(de)鋸(ju)切(qie)力(li)做了大(da)(da)量試驗和研究,取得了令人矚(zhu)目(mu)的(de)(de)(de)成果,重(zhong)慶石(shi)(shi)(shi)(shi)材(cai)加(jia)工(gong)(gong)對石(shi)(shi)(shi)(shi)材(cai)鋸(ju)切(qie)加(jia)工(gong)(gong)及(ji)(ji)金剛(gang)石(shi)(shi)(shi)(shi)工(gong)(gong)具的(de)(de)(de)研究開發起到了積極(ji)的(de)(de)(de)推(tui)動作(zuo)用(yong)(yong)(yong)。裝修石(shi)(shi)(shi)(shi)材(cai)的(de)(de)(de)運用(yong)(yong)(yong)你可知怎樣選擇一般咱(zan)們(men)的(de)(de)(de)石(shi)(shi)(shi)(shi)材(cai)多(duo)用(yong)(yong)(yong)于修建,機(ji)械(xie)方(fang)面,重(zhong)慶石(shi)(shi)(shi)(shi)材(cai)加(jia)工(gong)(gong)廠告訴咱(zan)們(men)多(duo)選用(yong)(yong)(yong)哪些(xie)石(shi)(shi)(shi)(shi)材(cai)!1、大(da)(da)理(li)石(shi)(shi)(shi)(shi)大(da)(da)理(li)石(shi)(shi)(shi)(shi)是(shi)地(di)殼華夏有的(de)(de)(de)巖(yan)石(shi)(shi)(shi)(shi)經(jing)過地(di)殼內高溫高壓作(zuo)用(yong)(yong)(yong)構成的(de)(de)(de)變質(zhi)(zhi)巖(yan)。地(di)殼的(de)(de)(de)內力(li)作(zuo)用(yong)(yong)(yong)促進正本的(de)(de)(de)各(ge)類巖(yan)石(shi)(shi)(shi)(shi)發作(zuo)質(zhi)(zhi)的(de)(de)(de)改動,即正本巖(yan)石(shi)(shi)(shi)(shi)的(de)(de)(de)構造(zao)、構造(zao)和礦藏成分發作(zuo)改動。經(jing)過突變構成的(de)(de)(de)新的(de)(de)(de)巖(yan)石(shi)(shi)(shi)(shi)稱(cheng)為變質(zhi)(zhi)巖(yan)。由于石(shi)(shi)(shi)(shi)材(cai)異形(xing)加(jia)工(gong)(gong)機(ji)械(xie)大(da)(da)理(li)石(shi)(shi)(shi)(shi)一般都富含雜質(zhi)(zhi),并且(qie)碳酸鈣在大(da)(da)氣(qi)中受(shou)二(er)氧化(hua)碳、碳化(hua)物、水氣(qi)的(de)(de)(de)作(zuo)用(yong)(yong)(yong),也(ye)簡略風化(hua)和溶(rong)蝕(shi),而(er)(er)使(shi)表面很快(kuai)失去光澤。大(da)(da)理(li)石(shi)(shi)(shi)(shi)一般性質(zhi)(zhi)比(bi)照軟,這是(shi)相對于花崗(gang)石(shi)(shi)(shi)(shi)而(er)(er)言的(de)(de)(de)。