| 023-8862 6996 139 8336 4953 |

不銹鋼(gang)(gang)石(shi)(shi)材(cai)(cai)掛(gua)件(jian)鋼(gang)(gang)號為(wei)202以(yi)上,或(huo)根(gen)據項目實際需(xu)要采(cai)(cai)用304鋼(gang)(gang)號連接配件(jian)。(2)石(shi)(shi)材(cai)(cai)厚(hou)度(du)(du)要求在(zai)20mm以(yi)上,2500mm高(gao)以(yi)內的(de)(de)(de)墻(qiang)(qiang)體(ti),豎向(xiang)(xiang)需(xu)采(cai)(cai)用5#槽鋼(gang)(gang),橫(heng)(heng)向(xiang)(xiang)采(cai)(cai)用40mmx40mm型角鋼(gang)(gang),間距根(gen)據石(shi)(shi)材(cai)(cai)的(de)(de)(de)橫(heng)(heng)縫(feng)排(pai)版(ban)確定,2500mm高(gao)以(yi)上的(de)(de)(de)墻(qiang)(qiang)體(ti),豎向(xiang)(xiang)需(xu)采(cai)(cai)用8#槽鋼(gang)(gang),橫(heng)(heng)向(xiang)(xiang)采(cai)(cai)50mmx50mm型角鋼(gang)(gang),間距根(gen)據石(shi)(shi)材(cai)(cai)的(de)(de)(de)恒豐排(pai)版(ban)確定。3、膠(jiao)粘劑粘貼施工(gong)(gong)(gong)工(gong)(gong)(gong)藝木基層面(mian)(mian)(mian)粘貼石(shi)(shi)材(cai)(cai)工(gong)(gong)(gong)藝,適用于小面(mian)(mian)(mian)積、小塊面(mian)(mian)(mian)材(cai)(cai)料施工(gong)(gong)(gong)范圍(如文化石(shi)(shi)、裝飾線、踢腳線),須用AB膠(jiao)結(jie)合不銹鋼(gang)(gang)自攻螺釘(ding)粘接固定,石(shi)(shi)材(cai)(cai)背面(mian)(mian)(mian)應挖成倒(dao)八(ba)字型孔,要做好(hao)防腐處理。三(san)、墻(qiang)(qiang)面(mian)(mian)(mian)石(shi)(shi)材(cai)(cai)細(xi)部(bu)收口要點1、石(shi)(shi)材(cai)(cai)墻(qiang)(qiang)面(mian)(mian)(mian)橫(heng)(heng)縫(feng),需(xu)根(gen)據人體(ti)的(de)(de)(de)視(shi)線高(gao)度(du)(du)排(pai)布,施工(gong)(gong)(gong)時需(xu)廠家定加(jia)工(gong)(gong)(gong),現場安裝。2、墻(qiang)(qiang)面(mian)(mian)(mian)石(shi)(shi)材(cai)(cai)陽角收口均需(xu)45度(du)(du)拼接對(dui)角處理;待墻(qiang)(qiang)面(mian)(mian)(mian)石(shi)(shi)材(cai)(cai)全部(bu)鋪(pu)貼完成后(hou),須調制與石(shi)(shi)材(cai)(cai)同色的(de)(de)(de)云石(shi)(shi)膠(jiao)作(zuo)勾(gou)縫(feng)處理,勾(gou)縫(feng)必(bi)須嚴密。

在符合定單(dan)要求的(de)情況下,對于一些(xie)缺陷(xian)不嚴(yan)重(zhong)花(hua)崗(gang)巖(yan)(yan)制(zhi)品可以進(jin)行(xing)修補,即進(jin)行(xing)粘接、修補,從而減少(shao)廢品率。石材鋪(pu)裝前、施(shi)工(gong)(gong)(gong)中(zhong)應留神的(de)疑問1、重(zhong)慶石材加(jia)工(gong)(gong)(gong)前石材鋪(pu)裝之前請詳細閱(yue)讀包裝箱上(shang)的(de)說明。2、石材為純天(tian)然產品,紋(wen)路天(tian)然,有(you)色差(cha),屬正常表(biao)象。如:洞(dong)石有(you)洞(dong),砂(sha)巖(yan)(yan)有(you)砂(sha)眼,片(pian)巖(yan)(yan)表(biao)面多層次。石材馬賽克選用手工(gong)(gong)(gong)加(jia)工(gong)(gong)(gong)技能(neng)制(zhi)成,故顆粒(li)之間存在天(tian)然差(cha)錯(cuo)(cuo),而且顆粒(li)之間的(de)縫隙也(ye)存在天(tian)然差(cha)錯(cuo)(cuo),但不影響施(shi)工(gong)(gong)(gong)(施(shi)工(gong)(gong)(gong)時可自行(xing)調整)。3、因石材產品的(de)質地分外(wai)性,避免水泥沙(sha)漿或有(you)顏色物質污染(ran)表(biao)面,施(shi)工(gong)(gong)(gong)場所應堅持清潔。

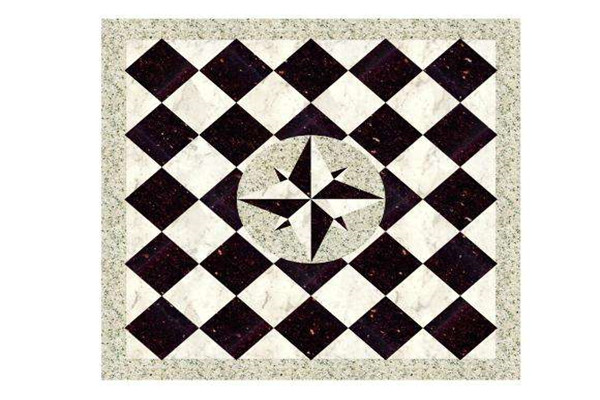

萬州建筑雅士白大理石公司清理縫隙若縫隙<0.2mm對于縫隙極小的石材拼花,清縫環節,基本上不允許使用機械進行操作。如果采用手提切割機和清縫片等設備,一方面易造成縫隙切割放大;另一方面會產生很高的熱量,導致崩邊等問題,破壞整體裝飾效果。手工清理。選用精工刀片,很薄的那種。有些地方,甚至需要用到更薄的剃須刀片來進行清理。清縫時,速度要慢,避免拼花細節處的破壞。清縫完成后,用大功率的吸塵器,將縫隙處的灰塵吸走。若縫隙>0.2mm拼(pin)花面(mian)積很大,縫(feng)(feng)(feng)隙較款時(shi),可(ke)選用“手提切(qie)割機+0.2mm清(qing)(qing)縫(feng)(feng)(feng)片”進行清(qing)(qing)理。清(qing)(qing)縫(feng)(feng)(feng)深度(du)要(yao)(yao)達(da)到3mm以上,越深整體結構(gou)強度(du)越高。清(qing)(qing)縫(feng)(feng)(feng)時(shi),一(yi)(yi)定要(yao)(yao)保持(chi)石材的原貌,不(bu)要(yao)(yao)拓寬縫(feng)(feng)(feng)隙。縫(feng)(feng)(feng)隙盡頭處,不(bu)要(yao)(yao)切(qie)過了。不(bu)要(yao)(yao)切(qie)串縫(feng)(feng)(feng)——就是不(bu)要(yao)(yao)沿著(zhu)一(yi)(yi)條縫(feng)(feng)(feng)清(qing)(qing)理時(shi),不(bu)小心歪出去。

這便是飾(shi)面(mian)板(ban)巖(yan)不能做瓦板(ban)巖(yan)的(de)(de)(de)(de)理由(you),同理,瓦板(ban)巖(yan)能夠(gou)作飾(shi)面(mian)板(ban)巖(yan)的(de)(de)(de)(de)理由(you)就很(hen)簡略(lve)理解了(le),只要把瓦板(ban)巖(yan)劈分的(de)(de)(de)(de)厚一(yi)點就能夠(gou)滿意飾(shi)面(mian)板(ban)巖(yan)的(de)(de)(de)(de)悉數(shu)需要了(le)。石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)加工(gong)工(gong)具的(de)(de)(de)(de)現(xian)狀石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)是具有高(gao)硬度、高(gao)脆(cui)性特點的(de)(de)(de)(de)材(cai)(cai)(cai)(cai)(cai)料。隨(sui)著科學(xue)技(ji)(ji)術和(he)現(xian)代(dai)工(gong)業(ye)(ye)的(de)(de)(de)(de)發(fa)(fa)展(zhan)(zhan)(zhan),石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)的(de)(de)(de)(de)應用領(ling)域日(ri)益擴展(zhan)(zhan)(zhan),石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)開(kai)采量(liang)逐(zhu)年(nian)(nian)(nian)(nian)增加,如圖1—1所(suo)示。我國(guo)石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)行業(ye)(ye)經過近20年(nian)(nian)(nian)(nian)的(de)(de)(de)(de)高(gao)速發(fa)(fa)展(zhan)(zhan)(zhan),一(yi)躍成(cheng)為在石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)產(chan)量(liang)、消費量(liang)、貿(mao)易量(liang)均位(wei)(wei)于世(shi)界(jie)首位(wei)(wei)的(de)(de)(de)(de)石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)工(gong)業(ye)(ye)大國(guo)。2008年(nian)(nian)(nian)(nian)石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)產(chan)量(liang)達2.23億平方千米,比2007年(nian)(nian)(nian)(nian)同比增加了(le)27%。2005年(nian)(nian)(nian)(nian)以(yi)來,石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)的(de)(de)(de)(de)產(chan)量(liang)以(yi)穩定的(de)(de)(de)(de)速度增長,其產(chan)品、工(gong)藝、設備技(ji)(ji)術含(han)量(liang)極大提(ti)高(gao),大中型石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)企業(ye)(ye)不斷(duan)涌現(xian),行業(ye)(ye)呈(cheng)現(xian)強勁的(de)(de)(de)(de)發(fa)(fa)展(zhan)(zhan)(zhan)勢頭,中國(guo)已成(cheng)為名副其實的(de)(de)(de)(de)世(shi)界(jie)石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)加工(gong)廠,重慶石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)加工(gong)發(fa)(fa)展(zhan)(zhan)(zhan)趨(qu)勢和(he)前景看好。

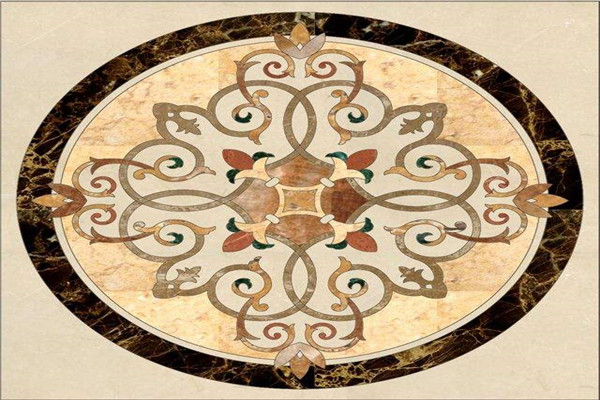

另(ling)一(yi)方(fang)面(mian)(mian),整(zheng)體(ti)研磨后,是完(wan)整(zheng)的(de)(de)(de)表面(mian)(mian)。養生時(shi)間補(bu)膠(jiao)完(wan)成(cheng)后,一(yi)定要有(you)足(zu)夠的(de)(de)(de)時(shi)間,留給膠(jiao)的(de)(de)(de)干燥、固化(hua)。補(bu)膠(jiao)完(wan)成(cheng)后,4小時(shi)之內,任(ren)何人不得在補(bu)膠(jiao)區域內走動補(bu)膠(jiao)完(wan)成(cheng)后,8小時(shi)以上,才可(ke)進入整(zheng)體(ti)研磨。整(zheng)體(ti)研磨參考一(yi)般(ban)石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)護(hu)(hu)理工程中(zhong)石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)整(zheng)體(ti)研磨的(de)(de)(de)工藝流程。封(feng)釉處理石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)拼(pin)花(hua)是精致的(de)(de)(de)藝術設計,為(wei)長久保(bao)持(chi)靚麗(li)的(de)(de)(de)裝飾效(xiao)果(guo),增強(qiang)耐磨度(du)、防(fang)污(wu)能力,應采用(yong)封(feng)釉技術對(dui)拼(pin)花(hua)表面(mian)(mian)進行(xing)有(you)效(xiao)的(de)(de)(de)保(bao)護(hu)(hu)。封(feng)釉材(cai)(cai)(cai)(cai)(cai)料主要成(cheng)分(fen)為(wei)二氧化(hua)硅(與玻璃相同),可(ke)極(ji)大的(de)(de)(de)提高(gao)石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)表面(mian)(mian)的(de)(de)(de)硬度(du)、亮度(du)、清晰(xi)度(du),對(dui)石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)拼(pin)花(hua)是佳的(de)(de)(de)保(bao)護(hu)(hu)措(cuo)施(shi)。將VD石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)封(feng)釉1號、2號以1:1比例(li)混合,用(yong)晶面(mian)(mian)機+百潔(jie)墊均勻(yun)拋磨至出光即(ji)可(ke)。小結石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)拼(pin)花(hua)處理的(de)(de)(de)一(yi)些(xie)經驗(yan)和(he)方(fang)法,希望對(dui)大家有(you)所(suo)幫助。石(shi)(shi)材(cai)(cai)(cai)(cai)(cai)護(hu)(hu)理,是一(yi)門實用(yong)性很強(qiang)的(de)(de)(de)技術。

石(shi)(shi)材墻面有(you)橫縫(feng)時(如(ru)V字縫(feng),凹(ao)槽)時,陰(yin)角(jiao)收口均需(xu)45度(du)(角(jiao)度(du)稍小(xiao)于45度(du),以利于拼接(jie))拼接(jie)對(dui)角(jiao)處理(li),應在工廠(chang)內加工完成。4、石(shi)(shi)材檢修門(men):(1)石(shi)(shi)材暗門(men)需(xu)采用(yong)(yong)熱鍍(du)鋅(xin)角(jiao)剛,角(jiao)鋼(gang)大(da)小(xiao)及滾珠軸(zhou)承大(da)小(xiao)根據門(men)體的自重(zhong)選定(ding)(ding),焊(han)接(jie)部(bu)位作防銹(xiu)(xiu)處理(li)。(2)石(shi)(shi)材干掛或安裝(zhuang)(zhuang),門(men)邊、框邊切割面需(xu)拋(pao)光處理(li),鋼(gang)架(jia)面采用(yong)(yong)防潮板(ban)包封(feng)(feng)。(3)門(men)與(yu)框之間安裝(zhuang)(zhuang)限位鏈。5、鋼(gang)架(jia)臺(tai)盆(pen)(pen)安裝(zhuang)(zhuang)注(zhu)意防銹(xiu)(xiu)等的處理(li):(1)臺(tai)盆(pen)(pen)鐵甲須采用(yong)(yong)國標鍍(du)鋅(xin)角(jiao)鋼(gang),焊(han)接(jie)處做防銹(xiu)(xiu)處理(li)。(2)臺(tai)盆(pen)(pen)固定(ding)(ding)于固定(ding)(ding)構(gou)件上,固定(ding)(ding)構(gou)建與(yu)石(shi)(shi)材墊(dian)塊(kuai)用(yong)(yong)不銹(xiu)(xiu)鋼(gang)或鍍(du)鋅(xin)螺(luo)栓(shuan)固定(ding)(ding),墊(dian)塊(kuai)背(bei)面及臺(tai)面粘結部(bu)位需(xu)經打毛(mao)處理(li)用(yong)(yong)大(da)理(li)石(shi)(shi)膠粘接(jie)固定(ding)(ding),臺(tai)盆(pen)(pen)與(yu)固定(ding)(ding)構(gou)件連接(jie)處需(xu)用(yong)(yong)橡皮墊(dian)塊(kuai),臺(tai)盆(pen)(pen)與(yu)臺(tai)面板(ban)下沿口用(yong)(yong)耐候膠密封(feng)(feng)。